- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China

Cast Tungsten Carbide

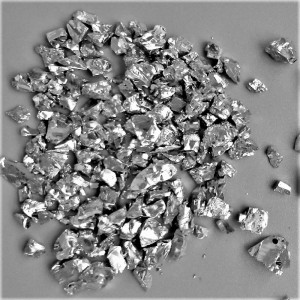

Cast Tungsten Carbide or Casting Tungsten Carbide, Tungsten Casting Carbide, is used as a reinforcing material for hard-facing of oil drilling tools, building-material production machines, grain-processing machines and other easily wearing components, which is made by melting tungsten metal (W) and tungsten mono-carbide (WC) together, a eutectic composition of WC and W2C is formed. This melt is cast and rapidly quenched to form extremely hard solid particles having a fine crystal structure. The solids are crushed and classified to various mesh sizes required.

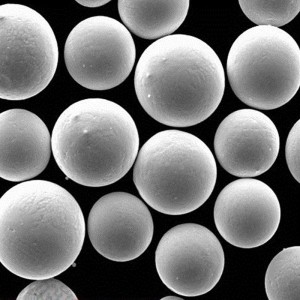

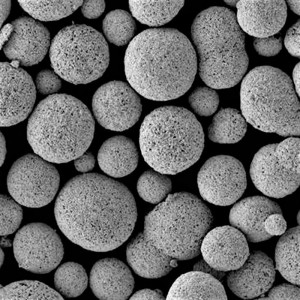

Spherical Cast Tungsten Carbide, is a kind of regularly spherical cast tungsten carbide with the microstructure is of homogeneous, dense and dentritic particle. It is widely used for exploiting drill bits, PCB drills, melting and penetrating, spray coating and built-up welding on worn surface.

Details

Tags

Technical Specification

|

No. |

Item |

Standard Specification |

|||

|

1 |

Casting WC |

Size (mesh/ mm) |

Chemical % Max each | ||

|

2 |

Casting

Tungsten Carbide |

YZ 5-10f | 5-10 | 4.0-2.0 | W 95-96% |

| YZ10-20f | 10-20 | 2.0-0.84 | Total C 3.8-4.1%, | ||

| YZ20-30f | 20-30 | 0.84-0.59 | Free C 0.08% | ||

| YZ30-40f | 30-40 | 0.59-0.42 | Fe 0.30, Si 0.02, V/O 0.05 | ||

| YZ40-60f | 40-60 | 0.42-0.25 | Cr/Ti 0.10 | ||

| YZ60-80f | 60-80 | 0.25-0.18 | Mo+Co+Ni 0.20 | ||

| YZ100-200f | 100-200 | 0.18-0.074 | Density 15.8-16.7g/cm3 | ||

| YZ200-400f | 200-400 | 0.074-0.038 | Micro-hardness HV1700-2500 | ||

|

3 |

Spherical

Casting Tungsten Carbide |

SYZ20-40 | 20-40 | 0.84-0.42 | W 95-96% |

| SYZ40-60 | 40-60 | 0.42-0.25 | Total C 3.8-4.1%, | ||

| SYZ60-80 | 60-80 | 0.25-0.18 | Free C 0.08% | ||

| SYZ60-100 | 60-100 | 0.25-0.15 | Fe 0.30, Si 0.02,V/O 0.05 | ||

| SYZ100-200 | 100-200 | 0.15-0.075 | Cr/Ti 0.10 | ||

| SYZ200-325 | 200-325 | 0.075-0.045 | Mo+Co+Ni 0.20 | ||

| SYZ100-325 | 100-325 | 0.15-0.045 | Density 15.8-16.7g/cm3 | ||

| SYZ325 | -325 | 0.045 | Micro-hardness HV2700-3300 | ||

|

4 |

Packing |

In sealed plastic bag, iron drum outside, 50/100kgs net. |

|||

Procurement Tips

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- Quality Inspection Including XRD/SEM/ICP/GDMS etc

- Full Scope of Trade Terms CPT/FOB/ CFR/CIP By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- ISO9001:2015 Certified & Rohs/REACH Regulations Approval

- Non-Disclosure Agreements

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu