- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

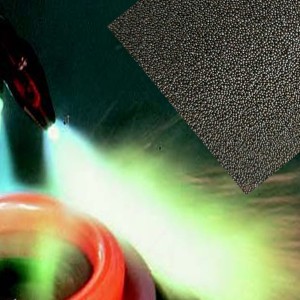

Cemented Carbide Hardsurfacing Powder

Description

Cemented Carbide Hard-surfacing Powder, including Tungsten Carbide based or Chromium Carbide based Thermal Spraying Powder (TSP), being spherical or nearly spherical dark gray powder with good flowability, processed by agglomerated and sintered (A+S) or sintered and crushed (S+C), features in unique properties such as good abrasion resistance, corrosion resistance and high temperature resistance, maximum operating temperature for tungsten carbide based is about 500°C, chromium carbide based one is about 700°C-870°C. Cemented Carbide Hard-surfacing Powder or Tungsten Carbide Hard-surfacing Powder or Thermal Spraying Powder is suitable for various kinds of spraying and plasma spraying welding etc in mining, petroleum, metallurgical industry, agricultural machinery, steel and construction industries.

Delivery

Cemented Carbide Hard-surfacing Powder at Western Minmetals (SC) Corporation can be delivered with Tungsten Carbide based such as WC-12Co, WC-17Co, WC-10Co4Cr, WC-10Ni, WC-12Ni, WC-17Ni, WC-15NiCr etc and Chromium Carbide based such as Cr3C2-20NiCr, Cr3C2-25NiCr etc in size of 10-30um, 10-45um, 20-59um powder etc, package of 25kg in plastic bag with iron drum outside.

Details

Tags

Technical Specification

Cemented Carbide Hard-surfacing Powder or Thermal Spraying Powder at Western Minmetals (SC) Corporation can be delivered with Tungsten Carbide based such as WC-12Co, WC-17Co, WC-10Co4Cr, WC-10Ni, WC-12Ni, WC-17Ni, WC-15NiCr etc and Chromium Carbide based such as Cr3C2-20NiCr, Cr3C2-25NiCr etc in size of 10-30um, 10-45um, 20-59um powder etc, package of 25kg in plastic bag with iron drum outside.

Thermal Spray Powder Cemented Carbide Hard-surfacing Powder

|

No. |

Item |

Standard Specification |

||||||

|

1 |

Grade |

T.C % |

Co % |

Cr % |

Ni % |

Fe % |

O % |

|

|

2 |

TSP42 | WC-12Co |

5.2-5.6 |

11.5-12.5 |

- |

- |

≤1.0 |

≤0.5 |

| TSP42D | WC-12Co |

5.2-5.6 |

11.5-12.5 |

- |

- |

≤0.15 |

≤0.5 |

|

| TSP43 | WC-17Co |

4.7-5.2 |

16.5-17.5 |

- |

- |

≤1.0 |

≤0.5 |

|

| TSP43D | WC-17Co |

4.7-5.2 |

16.5-17.5 |

- |

- |

≤0.15 |

≤0.5 |

|

| TSP45 | WC-10Co4Cr |

5.2-5.6 |

9.1-10.1 |

3.0-4.5 |

- |

≤1.0 |

≤0.5 |

|

| TSP45D | WC-10Co4Cr |

5.2-5.6 |

9.1-10.1 |

3.0-4.5 |

- |

≤0.15 |

≤0.5 |

|

| TSP46D | WC-9Co5Cr1Ni |

5.1-5.8 |

8.5-9.5 |

4.5-5.5 |

0.8-1.2 |

≤0.3 |

≤0.5 |

|

| TSP47D | WC-10Ni |

5.3-5.8 |

- |

- |

9.0-11.0 |

≤0.2 |

≤0.5 |

|

| TSP48D | WC-20Cr3C2-7Ni |

5.8-6.4 |

- |

20-23 |

6.0-8.0 |

≤0.5 |

≤0.5 |

|

| TSP49D | Cr3C2-37WC-18NiCoCr | 7.8-8.4 |

3.0-4.0 |

39.5-42.5 |

10.5-12.5 |

≤0.5 |

≤0.5 |

|

| TSP51D | Cr3C2-20NiCr |

9.7-10.7 |

- |

Balance |

15.0-17.0 |

≤0.15 |

≤0.5 |

|

| TSP52D | Cr3C2-25NiCr |

9.1-10.1 |

- |

Balance |

19.0-21.0 |

≤0.15 |

≤0.5 |

|

| TSP91D | WC-12Ni |

5.2-5.6 |

- |

- |

11.5-12.5 |

≤0.2 |

≤0.5 |

|

| TSP92D | WC-17Ni |

5.0-5.3 |

- |

- |

16.5-17.5 |

≤0.2 |

≤0.5 |

|

| TSP93D | WC-15NiCr |

5.0-5.4 |

- |

2.5-3.5 |

11.5-12.5 |

≤0.5 |

≤0.5 |

|

|

3 |

Density | WC Based |

Apparent Density ≥4.0 g/cm3 |

|||||

| Cr3C2 Based |

Apparent Density TSP49D ≥2.5g/cm3, TSP51D TSP52D ≥2.0 g/cm3 |

|||||||

|

4 |

Size | μm |

53-20 |

45-20 |

45-15 |

45-11 |

38-10 |

30-10 |

| Flow Rates/50g | WC Based |

≤18 |

≤18 |

≤18 |

≤18 |

≤18 |

≤30 |

|

| Cr3C2 Based |

- |

- |

- |

- |

- |

- |

||

|

5 |

Grain Morphology |

TSPXXD is spherical or nearly spherical by Agglomerated and Sintered |

||||||

|

6 |

Packing |

25kg or 50kgs in plastic bag with iron drum outside |

||||||

Procurement Tips

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- ISO9001:2015 Certified

- CPT/CIP/FOB/CFR Terms By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- Quality Inspection By Sate-of-the-art Facility

- Rohs/REACH Regulations Approval

- Non-Disclosure Agreements NDA

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment

Thermal Spray Powder

Hard-surfacing Powder

related products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu