- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

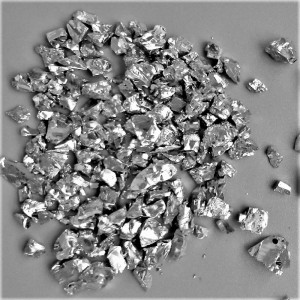

Chromium Carbide Cr3C2

Description

Chromium Carbide Cr3C2, an inorganic compound, gray powder with metallic luster, orthorhombic system structure, molecular weight 180.01, density 6.68g/cm3, melting point 1890°C, boiling point 3800°C, coefficient of thermal expansion 10.3×10-6/K, is indissoluble in water and resistant to acid and alkali. Chromium Carbide is a kind of cermet material which has good wear resistance, corrosion resistance, anti-oxidation performance in high temperature environment and high microhardness. Chromium Carbide Cr3C2 at Western Minmetals (SC) Corporation can be delivered in size of powder 0.5-500micron or 5-400mesh with package of 25kg, 50kg in plastic bag with iron drum outside.

Applications

Chromium Carbide Cr3C2 can be used as high temperature resistant, wear-resistant, oxidation resistant and acid resistant coating for aircraft engines and petrochemical mechanical components and devices to greatly improve the service life of machinery. Chromium Carbide Cr3C2 is commonly used as an additive of grain refiner to inhibit the growth of the alloy grains, and fine the crystalline grain in the production of cemented carbide and other wear-resistant and corrosion-resistant components. It is also expansively used to spray semiconductor film and as thermal spray material to protect the metal surface, or plasma spray in the metallurgy, electric power and petrochemical field.

Details

Tags

Technical Specification

| No. | Item | Standard Specification | |||||||

| 1 | Products | Cr3C2 | NbC | TaC | TiC | VC | ZrC | HfC | |

| 2 | Content % | Total C ≥ | 12.8 | 11.1 | 6.2 | 19.1 | 17.7 | 11.2 | 6.15 |

| Free C ≤ | 0.3 | 0.15 | 0.1 | 0.3 | 0.5 | 0.5 | 0.3 | ||

| 3 | Chemical

Impurity PCT Max each |

O | 0.7 | 0.3 | 0.15 | 0.5 | 0.5 | 0.5 | 0.5 |

| N | 0.1 | 0.02 | 0.02 | 0.02 | 0.1 | 0.05 | 0.05 | ||

| Fe | 0.08 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | ||

| Si | 0.04 | 0.01 | 0.01 | 0.02 | 0.01 | 0.005 | 0.005 | ||

| Ca | - | 0.005 | 0.01 | 0.01 | 0.01 | 0.05 | 0.05 | ||

| K | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | ||

| Na | 0.005 | 0.005 | 0.005 | 0.01 | 0.01 | 0.005 | 0.005 | ||

| Nb | 0.01 | - | 0.01 | 0.01 | 0.01 | 0.005 | 0.005 | ||

| Al | - | 0.005 | 0.01 | - | - | - | - | ||

| S | 0.03 | - | - | - | - | - | - | ||

| 4 | Size | 0.5-500micron or 5-400mesh or as customized | |||||||

| 5 | Packing | 2kgs in composite bag with iron drum outside, 25kgs net | |||||||

Chromium Carbide Cr3C2 can be used as high temperature resistant, wear-resistant, oxidation resistant and acid resistant coating for aircraft engines and petrochemical mechanical components and devices to greatly improve the service life of machinery. Chromium Carbide Cr3C2 is commonly used as an additive of grain refiner to inhibit the growth of the alloy grains, and fine the crystalline grain in the production of cemented carbide and other wear-resistant and corrosion-resistant components. It is also expansively used to spray semiconductor film and as thermal spray material to protect the metal surface, or plasma spray in the metallurgy, electric power and petrochemical field.

Procurement Tips

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- ISO9001:2015 Certified

- CPT/CIP/FOB/CFR Terms By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- Quality Inspection By Sate-of-the-art Facility

- Rohs/REACH Regulations Approval

- Non-Disclosure Agreements NDA

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment

Chromium Carbide Cr3C2

related products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu