- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

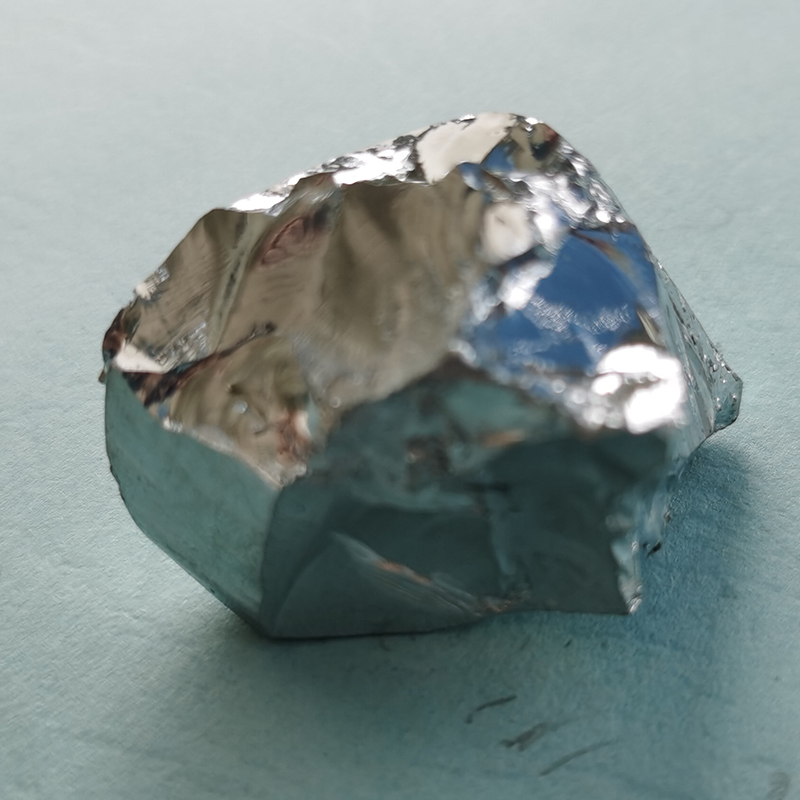

Europe style for Tin Ingot 99.99999% - High Purity Sulfur – WMC

Bismuth, odorless, silver white or reddish color metal with metallic luster, with a very high electrical resistance and the highest Hall effect, is a non-toxic and green metal, and stable in both dry and moist air with lower oxidation at room temperatures, and do not react with oxygen or water. High purity bismuth of 99.999% 5N and 99.9999% 6N purity By electrolytic refining from commercially marketed metal bismuth, or zone-refining process and by crystallization in electric and magnetic firlds is primarily used in the manufacturing of compound semiconductor materials, high purity alloys, thermoelectric converting elements, electronic cooling elements, and liquid carrier for the cooling in the atomic reactor etc. High Purity Bismuth at Western Minmetals (SC) Corporation with purity 99.999% 99.9999%, 99.99999% 5N 6N 7N purity is in size of shot, lump, chunk, ingot, bar and crystal or customized specification can be delivered, which is packed in composite aluminum bag with argon gas filled protection, carton box outside.

Bismuth Shot, tear drop shaped of approx 1-6mm diameter, or to be customized, density 9.78g/cm3, melting point 271.3°C and boiling point 1564°C, with 99.9% 3N, 99.99% 4N, 99.995% 4N5 and 99.999% 5N purity level. Bismuth is a non-toxic and green metal and stable in both dry and moist air at room temperatures, and do not react with oxygen or water with lower oxidation, not easily absorbed by body to cause cancer, it is used for pharmaceuticals and cosmetics. It is also used to replace lead in applications such as lead-free bullets, lead-free solder, and normally compound with Tin during the manufacturing of high-accuracy gears or bearings in mechanical industry to increased the durability and sustainability, or be used as a chemical reagent in medicine or chemical field. By the combination process of electrolytic refining, vacuum distillation, zone melting and granulating under inert gas protection from commercially marketed metal bismuth, Bismuth shot or granule, bead in form of tear-drop is specially used in production of vanadium cell, additive of titanium alloy, malleable iron, low-carbon steel or aluminum to improve machinability.

Details

Tags

|

No |

Item |

Standard Specification |

||

|

1 |

Sulfur (Sulphur)≥ |

5N |

6N |

|

|

99.999% |

99.9999% |

|||

|

2 |

ImpurityPPMwt Max each |

Al |

0.5 |

0.10 |

|

Cu |

0.2 |

0.05 |

||

|

Fe |

0.5 |

0.10 |

||

|

Ni |

0.5 |

0.10 |

||

|

Zn |

0.5 |

0.10 |

||

|

As |

0.5 |

0.20 |

||

|

Co |

0.5 |

0.05 |

||

|

Mn |

0.5 |

0.05 |

||

|

Pb |

0.5 |

0.05 |

||

|

Sn |

0.5 |

0.10 |

||

|

Cd |

- |

0.05 |

||

|

Se |

1.0 |

- |

||

|

Si |

1.5 |

0.10 |

||

|

Total |

≤10ppm |

≤1ppm |

||

|

3 |

Size | -60mesh powder, D2-7mm tablet, 0.5-5.0 or ≤25mm lump | ||

|

4 |

Packing |

1kgs in polyethylene bottle with composite bag outside |

||

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- Quality Inspection Including XRD/SEM/ICP/GDMS etc

- Full Scope of Trade Terms CPT/FOB/ CFR/CIP By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- ISO9001:2015 Certified & Rohs/REACH Regulations Approval

- Non-Disclosure Agreements

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment