- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

Good Quality Cast Wc Composite Rod - Tantalum-Niobium Carbide TaNbC – WMC

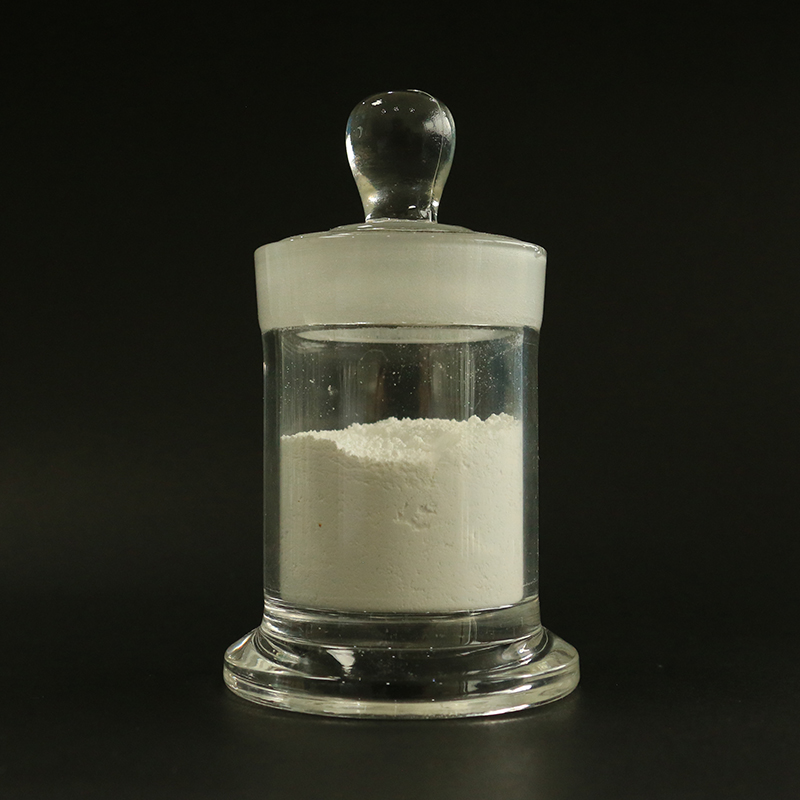

Yttria-stabilized Zirconia YSZ, ZrO2+Y2O3, is a non-toxic, odorless ceramic material. ZrO2 is monoclinic crystal at room temperature, the phase transformation temperature range of Zirconia is changed to produce stable cubic and tetragonal crystals at room temperature by adding Yttria. Known as “ceramic steel”, Yttria-stabilized Zirconia is usually prepared by hot pressing, dry pressing and isostatic pressing sintering.

As its phase transformation toughening mechanism, Yttria stabilized tetragonal Zirconia crystal ceramic has excellent mechanical properties such as high strength, high fracture toughness, high bending strength, mechanical impact resistance and high wear resistance at room temperature, high ionic conductivity, and excellent chemical corrosion resistance, good stability to acid, alkali, glass and molten metal except sulfuric acid and hydrofluoric acid. With ultra-fine crystal particle size, particle uniformity and reasonable composition ratio, Yttrium stabilized Zirconia has become the primary material for manufacturing oxygen sensors, high-temperature solid fuel cells, piezoelectric ceramics, ferroelectric ceramics, oxygen pumps, cutting tools and as structural ceramic, ceramic ferrule and sleeve, electronic ceramics, super refractory material, optical communication devices and oxygen fuel battery etc.

Yttria-stabilized Zirconia YSZ at Western Minmetals (SC) Corporation can be delivered in composition rate of ZrO2 86% + Y2O3 14% in size of powder or ceramic parts as customer’s drawings with package of 10-20kgs in wooden case.

Details

Tags

|

No. |

Item |

Standard Specification |

|||||

|

1 |

Grade |

90:10 |

80:20 |

70:30 |

60:40 |

50:50 |

|

|

2 |

ChemicalPCT |

Ta |

84.4±1.5 | 71.5±1.5 | 65.6±1.5 | 56.0±1.3 | 46.9±1.3 |

|

Nb |

8.85±1.0 | 21±1.0 | 26.6±1.2 | 35.0±1.3 | 44.3±1.5 | ||

|

T.C |

6.75±0.3 | 7.3±0.3 | 7.8±0.3 | 8.2±0.3 | 8.8±0.3 | ||

|

F.C |

≤0.15 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.15 | ||

|

3 |

ImpurityPCTMax Each |

Co/Mo/Cr |

0.10 | 0.10 | 0.10 | 0.10 | 0.10 |

|

Si |

0.02 | 0.02 | 0.02 | 0.02 | 0.02 | ||

|

Fe |

0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

|

Ni |

0.04 | 0.04 | 0.04 | 0.04 | 0.04 | ||

|

K/Na |

0.008 | 0.008 | 0.008 | 0.008 | 0.008 | ||

|

Mn |

0.05 | 0.05 | 0.05 | 0.05 | 0.05 | ||

|

Sn/Ca |

0.01 | 0.01 | 0.01 | 0.01 | 0.01 | ||

|

Al |

0.015 | 0.015 | 0.015 | 0.015 | 0.015 | ||

|

N |

0.25 | 0.20 | 0.25 | 0.25 | 0.25 | ||

|

Ti |

0.20 | 0.30 | 0.30 | 0.30 | 0.30 | ||

|

W |

0.20 | 0.35 | 0.35 | 0.35 | 0.35 | ||

|

O |

0.2, 0.25, 0.35 |

||||||

|

4 |

Size (FSSS µm) |

1.0-1.2, 1.2-1.5, 1.5-3.5 |

|||||

|

5 |

Packing |

2kgs in composite bag with iron drum outside, 25kg net |

|||||

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- Quality Inspection Including XRD/SEM/ICP/GDMS etc

- Full Scope of Trade Terms CPT/FOB/ CFR/CIP By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- ISO9001:2015 Certified & Rohs/REACH Regulations Approval

- Non-Disclosure Agreements

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment