- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

Molybdenum Wire | Rod | Disc

Description

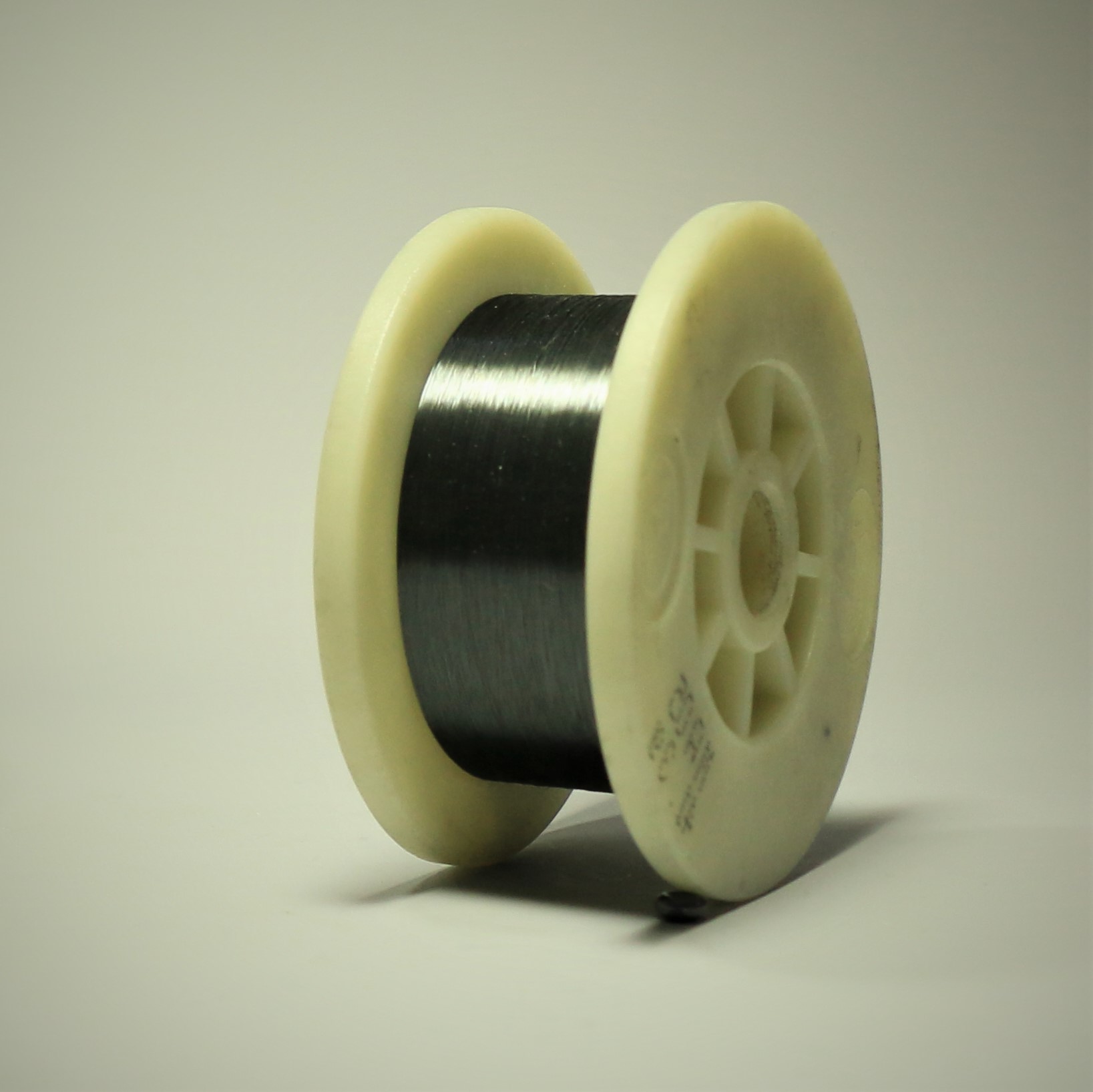

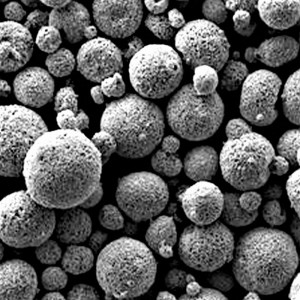

Spray Molybdenum Wire or Molybdenum Spraying Wire 99.95%, D1.41-2.3mm, D3.175mm, metallic luster appearance, is processed by powder metallurgical procedure. With a good wear resistance, high-temperature tensile strength and corrosion resistance, Molybdenum Spray Wire has become an indispensable material for surface hardening and brazing, which is thermically sprayed by Wire flame spray, Powder flame spray, Electric ARC spray, HOVF etc on surfaces of working parts exposed to high mechanical loads to increase their abrasion resistance such as automobile parts, piston rings, shift elements, high-temperature field of molybdenum furnace etc.

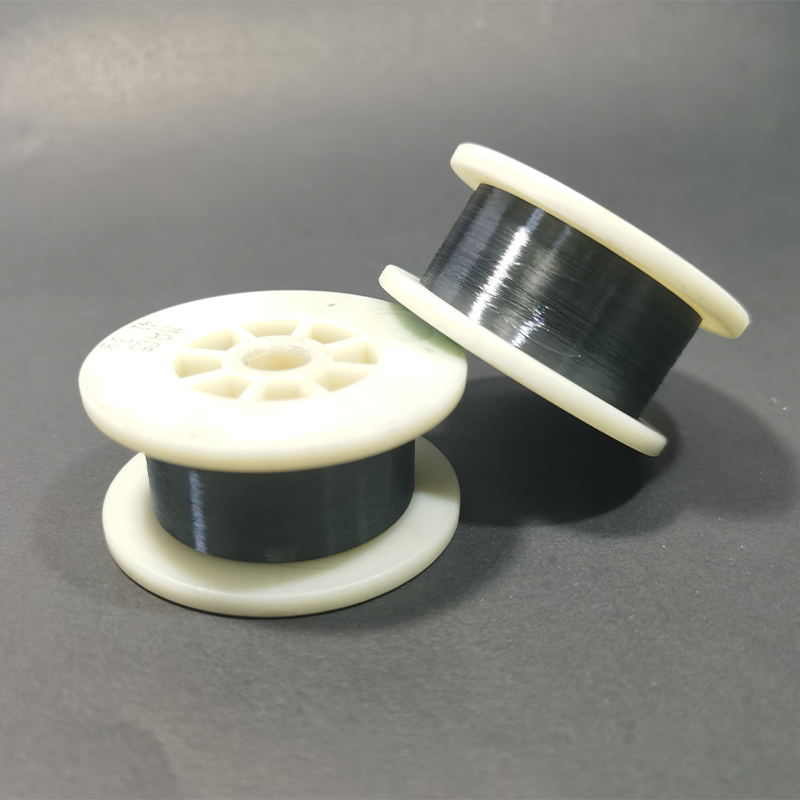

Black Molybdenum Wire 99.95%, D0.041-2.0mm, black surface with graphite coating in coil or straight state, exhibits excellent tensile strength, small elongation ratio, high cutting precision, high enduring and long-lasting. Black molybdenum wire is widely used in making heating parts for electronic vacuum device, wire cutting, mandrels of tungsten coiled wire, magnetron grids for lamps, locating rods and leading in pins and for redrawing purpose.

White Molybdenum Wire 99.95%, D0.05-3.0mm, or Cleaned Molybdenum Wire, good bright and shiny surface without oxidation by removing the graphite coating on the surface with electrolytic cleaning or hydrogen-sintered cleaning, features high strength, high conductivity, quick cutting speed and longer service life. Cleaned molybdenum wire is used for replacing black molybdenum wires as lamp holders, connecting materials, wire cutting machine, electric light source parts, electric vacuum components, heating elements and refractory parts in high temperature furnaces.

Details

Tags

Technical Specification

Spray Molybdenum Wire

With advanced production and processing technology and sophisticated testing and analysis equipment and fully experienced operation, Western Minmetals (SC) Corporation is committed to deliver Molybdenum wire and other Molybdenum products satisfactory to customers worldwide. Welcome customized need to provide the perfect solutions.

| Commodity | Standard Specification | |||

| Size mm | Weight per Pool | Pool Dia mm | ||

| White Molybdenum Wire | 0.151-0.28 | 750mg | 112 | |

| 0.281-1.00 | 6000mg | 280 | ||

| Molybdenum Wire | 0.041-0.11 | 5-20kg | 120 | |

| 0.111-0.40 | 5-20kg | 120 | ||

| 0.41-1.40 | 5-20kg | 350 | ||

| 1.41-2.00 | 5-20kg | 450 | ||

| Spray Molybdenum Wire | 1.41-1.50 | 4-10kg | 250-500m | 600/450 |

| 1.51-1.62 | 4-10kg | 220-480m | 600/450 | |

| 1.91-2.00 | 5-12kg | 170-380m | 600/450 | |

| 2.21-2.30 | 5-12kg | 130-280m | 600/450 | |

| 2.31-2.40 | 6-16kg | 130-350m | 600 | |

| 3.10-3.18 | 6-16kg | 80-200m | 600 | |

| Packing | In plywood case, iron drum or carton box, 25kg or 50kg net. | |||

| Commodity | Standard Specification | |||

| Purity | Size & Dimension | |||

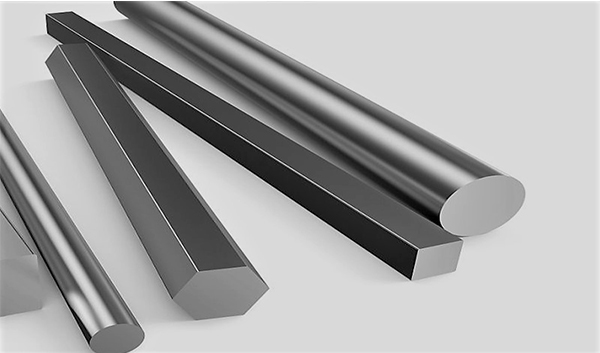

| Molybdenum Rod | 99.95% | D(2.0-15.0) mm x L(1.3-100) m | ||

| Molybdenum Bar | 99.95%, 99.9% | (12-20) x (12-20) x (500-530) mm, D(16-23) x (300-450) mm | ||

| Molybdenum Plate | 99.95% | (40-200) x (11-35) x (150-300) mm, (0.1-1.0) x (50-300) x L mm | ||

| Molybdenum Foil | 99.93% | Thickness (0.01-0.08) x Width (50-120) x L mm | ||

| Molybdenum Pipe | 99.93% | OD(0.5-15) x Wall thickness (0.2-0.5) mm | ||

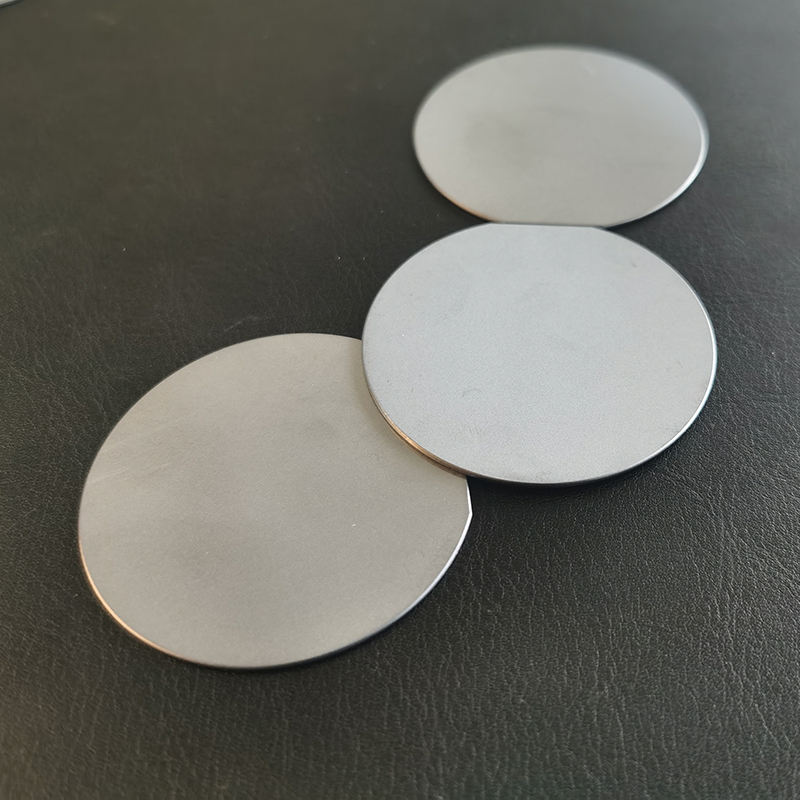

| Molybdenum Disc | 99.93% | D(7-100) x Thickness (0.8-4.0)mm | ||

| Packing | In plywood case, iron drum or carton box, 25kg or 50kg net. | |||

Molybdenum Rod or Bar 99.95%, silver-grey appearance, is of different state in black or polished, coiling or straightened, forged or grind, and drawn or annealed for different usage, which shares the properties of molybdenum of high melting point, good thermal conductivity and low thermal expansion. It is founded in fabricating heating elements, electronic components, cathode supports for radar devices, vacuum plating, glass fiber, steel smelting additive, shield material for nuclear, electrical light sources, power tube components and silicon rectifier mounts, and for drawing molybdenum wire.

Molybdenum Plate 99.95% can be supplied in a shiny, matte, or as-rolled in surface condition, and finds application in fabrication of furnace structural components for high temperature HIP, vacuum furnaces and hydrogen atmosphere furnace for sapphire growing, quartz glass melting, rare earth melting etc where the working temperature is above 1500°C, or as starting material for manufacturing electronic component, disks, foils, and plate electrode.

Molybdenum Disc 99.95% is used as an electronic component of high power and high reliability semiconductor for heat dissipation, and for contact material in silicon controlled rectifiers diodes, transistors and thyristors GTO’s, and as heat sink bases in ICs, LSI’s and hybrid circuits in the electrical and electronic industries.

Procurement Tips

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- ISO9001:2015 Certified

- CPT/CIP/FOB/CFR Terms By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- Quality Inspection By Sate-of-the-art Facility

- Rohs/REACH Regulations Approval

- Non-Disclosure Agreements NDA

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment

Spray Molybdenum Wire

related products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu