- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

Details

Tags

| Commodity | Item | Standard Specification | ||

| Tungsten Carbide Pellet Cemented Carbide WC Pellet |

Grade | YQ1 | YQ2 | YQ3 |

| Co % | 3.5-4.0 | 5.7-6.3 | 6.5-7.2 | |

| WC %min | Balance | Balance | Balance | |

| Total Carbon % | 5.5-5.9 | 5.4-5.8 | 5.4-5.8 | |

| Chemical | Free Carbon 0.1%, Ti 0.5%, Fe 0.5%, O 1.0% | |||

| Density g/cm3 | 14.8-15.3 | 14.8-15.0 | 14.5-15.0 | |

| HV kg/mm2 | ≥1400 | ≥1300 | ≥1300 | |

| Porosity | A04 B04 C04 | A04 B04 C02 | A04 B04 C04 | |

| Microstructure | No de-carbonization and Cobalt pools | |||

| Size | 10-20 Mesh , 14-20 Mesh , 20-30 Mesh, 30-40 Mesh | |||

| Packing | In iron drum with inner plastic bag, 25kg or 50kg net weight. | |||

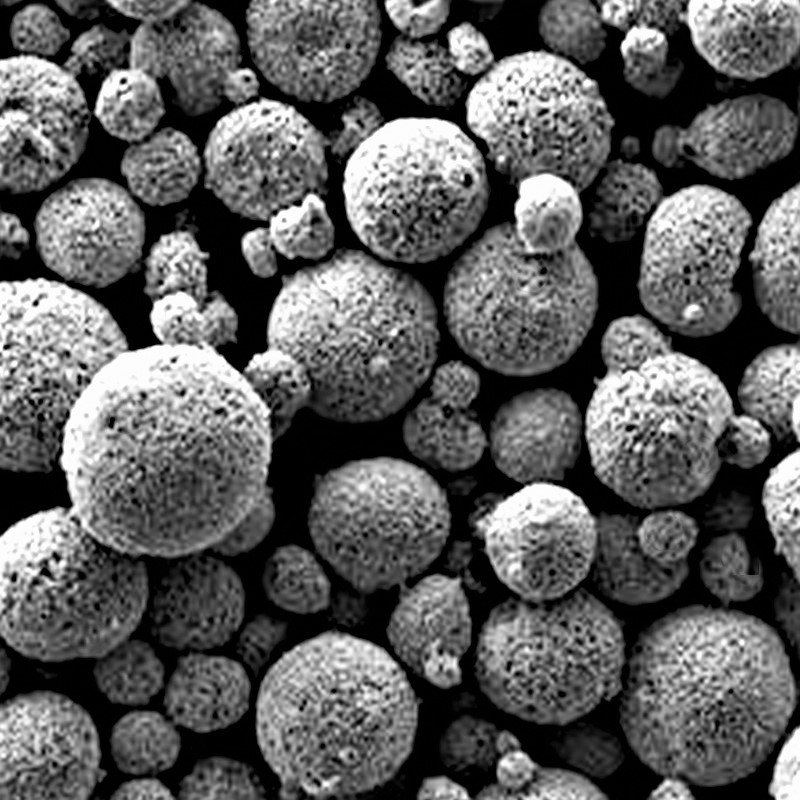

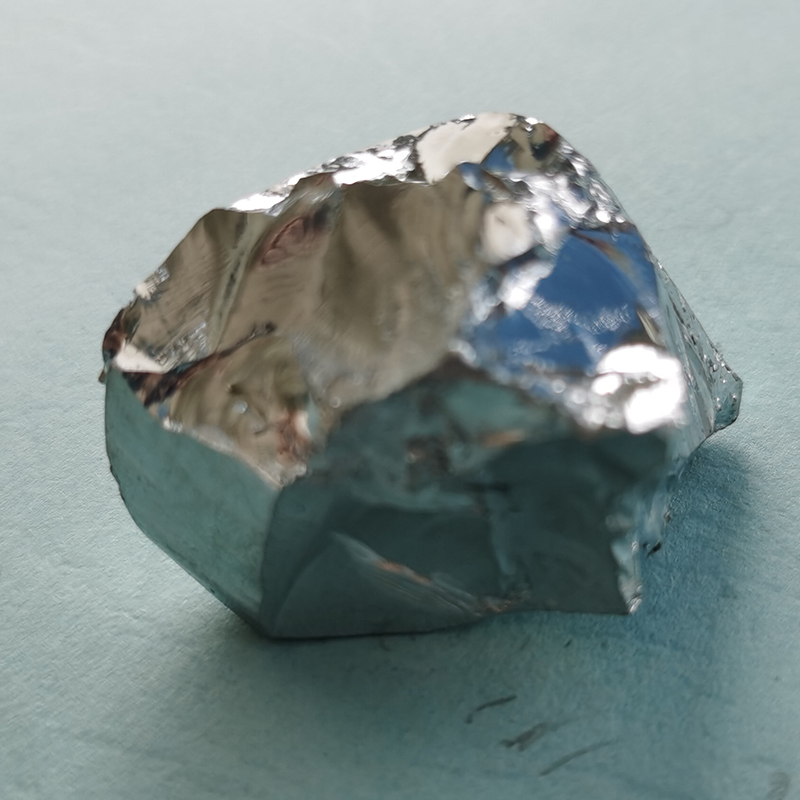

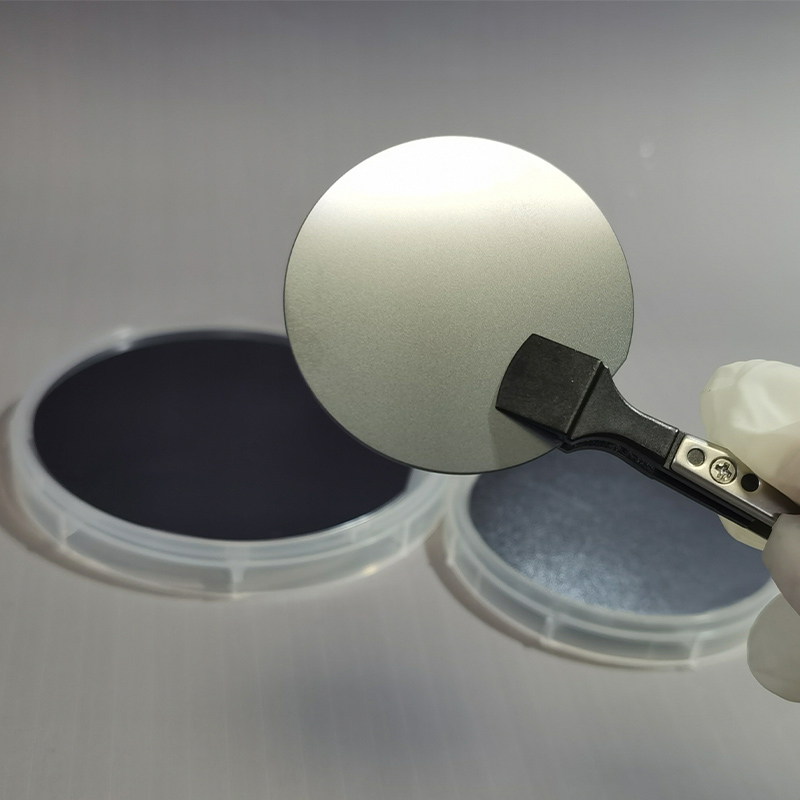

Tungsten Carbide Pellet or Cemented Carbide Pellet at Western Minmetals (SC) Corporation can be delivered in YQ1, YG2, YQ3 grade of Cobalt content 4%, 6% and 7% respectively with size of 10-20, 14-20, 20-30 and 30-40 mesh with package of 25kgs in plastic bag with iron drum outside, or as customized specification to reach the perfect solution.

Tungsten Carbide Pellet is for hard-surfacing to increase significantly the service life after welding onto the surface of the tools to form a hardened wear-resistant layer to against abrasive wear, and spraying wear parts in mining and oil drilling field, and for built-up welding to improve substantially the hardness, wear resistance and corrosion resistance of the surface of the machined parts. Tungsten carbide pellet is also widely used as punching and stamping machine parts, impact-resistant forging die, hot forging die and finished rollers, engineering machinery, metallurgical as well as mining industry etc.

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- ISO9001:2015 Certified

- CPT/CIP/FOB/CFR Terms By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- Quality Inspection By Sate-of-the-art Facilit

- Rohs/REACH Regulations Approval

- Non-Disclosure Agreements NDA

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment