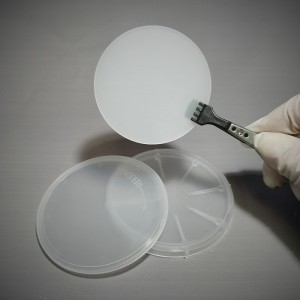

Silicon Carbide SiC at Western Minmetals (SC) Corporation can be provided in the size of 2″ 3‘ 4“ and 6″ (50mm, 75mm, 100mm, 150mm) diameter, with n-type, semi-insulating or dummy wafer for industrial and laboratory application.Any customized specification is for the perfect solution to our customers worldwide.

| Linear Formula | SiC |

| Molecular Weight | 40.1 |

| Crystal structure | Wurtzite |

| Appearance | Solid |

| Melting Point | 3103±40K |

| Boiling Point | N/A |

| Density at 300K | 3.21 g/cm3 |

| Energy Gap | (3.00-3.23) eV |

| Intrinsic resistivity | >1E5 Ω-cm |

| CAS Number | 409-21-2 |

| EC Number | 206-991-8 |

| No. | Items | Standard Specification | |||

| 1 | SiC Size | 2" | 3" | 4" | 6" |

| 2 | Diameter mm | 50.8 0.38 | 76.2 0.38 | 100 0.5 | 150 0.5 |

| 3 | Growth Method | MOCVD | MOCVD | MOCVD | MOCVD |

| 4 | Conductivity Type | 4H-N, 6H-N, 4H-SI, 6H-SI | |||

| 5 | Resistivity Ω-cm | 0.015-0.028; 0.02-0.1; >1E5 | |||

| 6 | Orientation | 0°±0.5°; 4.0° towards <1120> | |||

| 7 | Thickness μm | 330±25 | 330±25 | (350-500)±25 | (350-500)±25 |

| 8 | Primary Flat Location | <1-100>±5° | <1-100>±5° | <1-100>±5° | <1-100>±5° |

| 9 | Primary Flat Length mm | 16±1.7 | 22.2±3.2 | 32.5±2 | 47.5±2.5 |

| 10 | Secondary Flat Location | Silicon face up: 90°, clockwise from prime flat ±5.0° | |||

| 11 | Secondary Flat Length mm | 8±1.7 | 11.2±1.5 | 18±2 | 22±2.5 |

| 12 | TTV μm max | 15 | 15 | 15 | 15 |

| 13 | Bow μm max | 40 | 40 | 40 | 40 |

| 14 | Warp μm max | 60 | 60 | 60 | 60 |

| 15 | Edge Exclusion mm max | 1 | 2 | 3 | 3 |

| 16 | Micropipe Density cm-2 | <5, industrial; <15, lab; <50, dummy | |||

| 17 | Dislocation cm-2 | <3000, industrial; <20000, lab; <500000, dummy | |||

| 18 | Surface Roughness nm max | 1(Polished), 0.5 (CMP) | |||

| 19 | Cracks | None, for industrial grade | |||

| 20 | Hexagonal Plates | None, for industrial grade | |||

| 21 | Scratches | ≤3mm, total length less than substrate diameter | |||

| 22 | Edge Chips | None, for industrial grade | |||

| 23 | Packing | Single wafer container sealed in aluminum composite bag. | |||

Silicon Carbide SiC 4H/6H high quality wafer is perfect for the manufacturing of many cutting-edge superior fast, high-temperature & high-voltage electronic devices such as Schottky diodes & SBD, high-power switching MOSFETs & JFETs, etc. It is also a desirable material in the research & development of insulated-gate bipolar transistors and thyristors. As an outstanding new generation semiconducting material, Silicon Carbide SiC wafer also serves as an efficient heat spreader in high-power LEDs components, or as a stable and popular substrate for growing GaN layer in favor of future targeted scientific exploration.

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- ISO9001:2015 Certified

- CPT/CIP/FOB/CFR Terms By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- Quality Inspection By Sate-of-the-art Facility

- Rohs/REACH Regulations Approval

- Non-Disclosure Agreements NDA

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment