- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

Tungsten Carbide Ready-to-Press Powder

Description

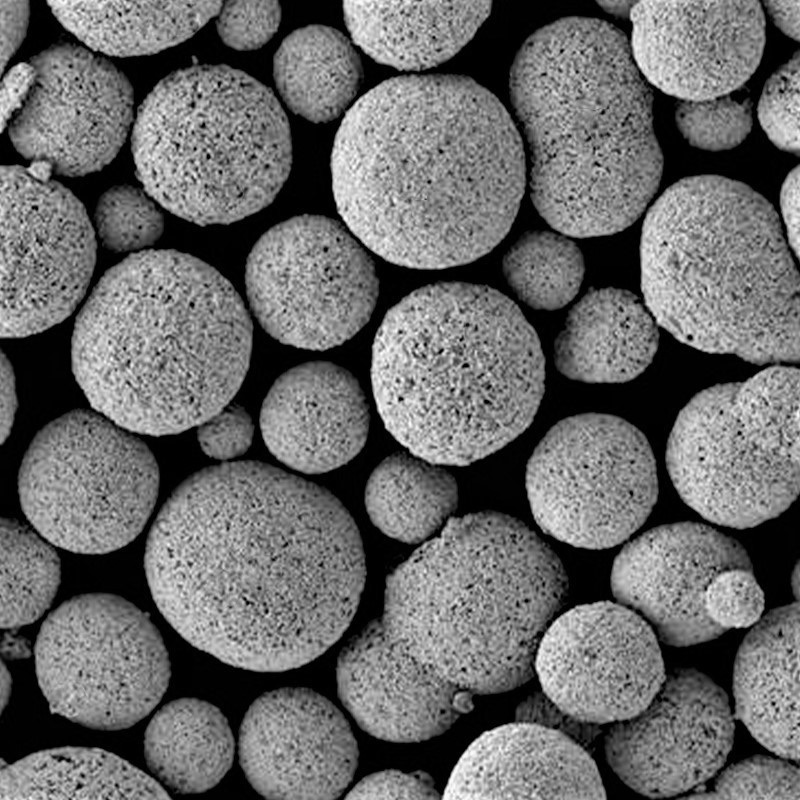

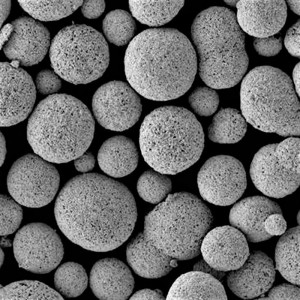

Tungsten Carbide Ready to Press Powder ( RTP powder) or Tungsten Carbide Grade Powder, with appearance of spherical particles gray color, is free-flowing powder as basic material in the production of sintered cemented carbide product. By uses the most advanced doping paraffine production process and spray drying technology, Tungsten carbide ready to press powder RTP is shaped into spherical granule with excellent flow-ability after ball milled, fully mixed and spray dried, each granule contain the constituent of a specified grade, such as tantalum carbide TaC, titanium carbide TiC, niobium carbide NbC, tantalum-niobium carbide TaNbC and other additive as inhibitors with cobalt or nickel as the binder to get superior performance. With excellent spherical morphology, perfect flowability and minimal residual moisture, RTP or Grade powder is an ideal grade powder to be used as the starting material to produce Cemented Carbide parts such as solid cutting tools, drilling tools, downhole tools, wear parts and other precision carbide components.

Delivery

Western Minmetals (SC) Corporation has the experience and technical team dedicated to develop and provide RTP powder to meets your specific requirements, several series RTP or Grade Powder with different grain sizes and formulations are available including ZK (ZK10μf, ZK30μf, ZK20, ZK30), YG (YG6, YG8, YG10, YG10C, YG11…), and ZP (ZP10, ZP25, ZP35) etc or can be delivered as customized grade to reach the perfect solution.

Details

Tags

Technical Specification

Tungsten Carbide Ready to Press Powder

(RTP Powder)

Western Minmetals (SC) Corporation has the experience and technical team dedicated to develop and provide RTP powder to meets your specific requirements, several series RTP or Grade Powder with different grain sizes and formulations are available including ZK (ZK10μf, ZK30μf, ZK20, ZK30), YG (YG6, YG8, YG10, YG10C, YG11…), and ZP (ZP10, ZP25, ZP35) etc or can be delivered as customized grade to reach the perfect solution.

Tungsten Carbide Ready to Press Powder ( RTP powder) or Tungsten Carbide Grade Powder, with excellent spherical morphology, perfect flowability and minimal residual moisture, is an ideal grade powder to be used as the starting material to produce Cemented Carbide parts such as solid cutting tools, drilling tools, downhole tools, wear parts and other precision carbide components.

|

NO. |

ITEM |

STANDARD SPECIFICATION |

|||||||

|

1 |

Grade |

Co% |

Size µm |

S/50g |

Bulk Density |

Coercive force KA/m |

Density g/cm3 |

HRA |

TRSN/mm2 |

|

2 |

ZK10µF | 6 | 0.6-0.8 | 30-40 | 3.0-3.6 | 24.7-29.0 | 14.70-14.95 | 92.5 |

2000 |

| ZK30µF | 10 | 0.6-0.8 | 30-45 | 2.8-3.3 | 19.0-24.0 | 14.30-14.50 | 91.5 |

2500 |

|

| ZK20 | 8 | 1.2-2.0 | 30-40 | 3.0-3.6 | 12.5-16.8 | 14.90-15.10 | 90.0 |

2200 |

|

| ZK30 | 6 | 30-45 | 2.9-3.4 | 10.0-15.0 | 14.60-14.90 | 89.5 |

2300 |

||

| YG6 | 6 | 2.4-4.0 | 36 | 3.55 | 12.0-17.0 | 14.70-15.10 | 91.5 |

2200 |

|

| YG6C | 6 | 10-15 | 30-40 | 3.0-3.6 | 6.4-8.3 | 14.85-15.00 | 89.5 |

2200 |

|

| YG8 | 8 | 2.4-4.0 | 36 | 3.24 | 10.0-15.0 | 14.60-14.90 | 89.0 |

2400 |

|

| YG10 | 10 | 2.4-4.0 | 40 | 3.24 | 9.0-12.0 | 14.40-14.70 | 88.0 |

2400 |

|

| YG10C | 10 | 10-15 | 30-40 | 3.0-3.6 | 5.5-8.2 | 14.35-14.55 | 87.0 |

2450 |

|

| YG11 | 11 | 2.4-4.0 | 30 | 3.50 | 8.0-13.0 | 14.20-14.60 | 87.0 |

2400 |

|

| YG11C | 11 | 10-15 | 35 | 3.75 | 5.9-9.0 | 14.10-14.50 | 87.5 |

2500 |

|

| YG15C | 15 | 2.4-4.0 | 31 | 2.95 | 7.0-11.0 | 13.90-14.20 | 97.5 |

2600 |

|

| YG20C | 20 | 2.4-4.0 | 30-45 | 2.8-3.8 | 5.0-6.0 | 13.45-13.65 | 83.5 |

2500 |

|

| ZP10-1 | 8.5 | 37 | 2.6-3.0 | 10.5-15.0 | 11.1-11.35 | 91.5 |

|

||

| ZP25 | 8.5 | 35 | 2.7-3.1 | 12.5-15.5 | 12.50-12.70 | 91.4 |

1800 |

||

| ZP35 | 10 | 30 | 3.0-3.6 | 11.5-15.5 | 12.60-12.80 | 90.5 |

2000 |

||

|

3 |

Packing |

25kg or 50kgs in plastic bag with iron drum outside |

|||||||

Procurement Tips

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- ISO9001:2015 Certified

- CPT/CIP/FOB/CFR Terms By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- Quality Inspection By Sate-of-the-art Facility

- Rohs/REACH Regulations Approval

- Non-Disclosure Agreements NDA

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment

Tungsten Carbide Ready to Press Powder (RTP)

related products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu