- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

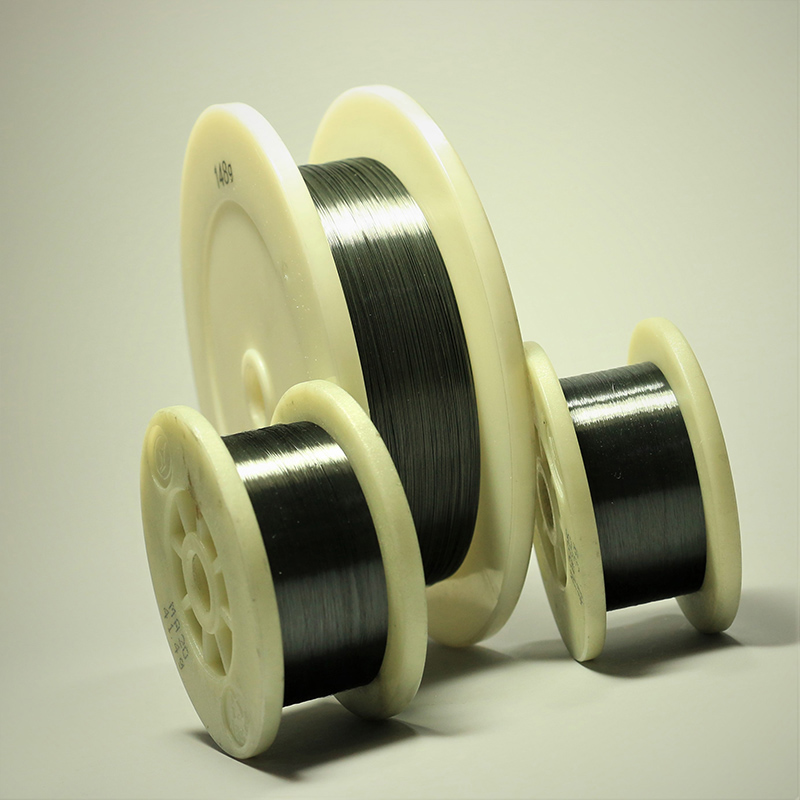

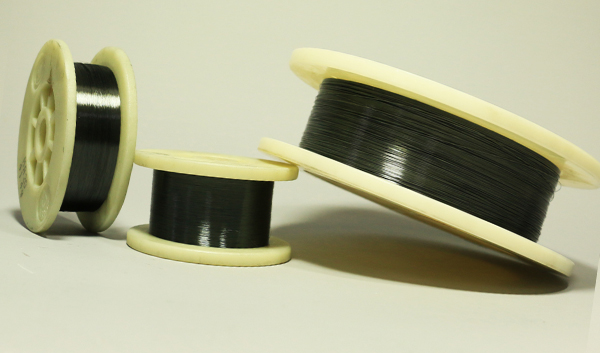

Tungsten Wire

Description

Black Tungsten Wire 99.95% D5-1800um, regularly black covered with graphite coating, has high melting point of 3422° C, low of thermal expansion coefficient, low vapor pressure, good electrical and thermal conductivity. It is essential for the production of lighting products such as single or double spiral lamp wire, fluorescence lamp wire, energy-saving lamp wire, single-end halogen lamp wire, Hi-temp lamp wire, twisted tungsten wire, tungsten heating element etc.

White Tungsten Wire or Cleaned Tungsten Wire, 99.95% D5-1800um, metallic luster surface after surface graphite removal, is of uniform in diameter, stress release, improved winding and Hi-temp properties. Cleaned tungsten wire is replacing black tungsten wire for the production of coiled incandescent lamp filaments, cathode and support structures for power tubes, filaments for auto lamps, fluorescent lamps, high pressure halogen lamps, heating elements and evaporation sources in metalizing processes etc.

Delivery

With advanced production and processing technology and sophisticated testing and analysis equipment and fully experienced operation, Western Minmetals (SC) Corporation is committed to provide the perfect solutions to our customers worldwide with high quality black tungsten wire, white tungsten wire, tungsten filament, tungsten twisting wire, conductor wire, tungsten heater, doped tungsten wire, non-sag tungsten wire, tungsten rhenium wire, tungsten molybdenum wire etc.

Details

Tags

Technical Specification

Tungsten-Rhenium

Tungsten-Molybdenum

Molybdenum-Tungsten Wire MW or Tungsten-Molybdenum WMo, MW20, MW30 and MW50, D0.03-11mm, is characterized by higher recrystallization temperature, higher strength, better formability, good performance at high temperatures, improved corrosion resistance and enhanced etchability. It finds typical applications in making thermo-conductive wire, thermocouple sheath, spark profile cutting wire, sputter targets for coating technology, thin film transistors, heating element and other components.

Tungsten-Rhenium Wire WRe, D12-1800um, D3-7um, is the alloying of tungsten with rhenium 1%, 3%, 5% and 25% Re by powder metallurgy technology. With surface uniformly clean and free of discoloration, Tungsten- Rhenium wire is mainly used for the production of dual tungsten rhenium wire, thermo-conductive wire, thermocouple, electrode of high-performance shock-proof lamp, electrodes of laser and electron tube, heater and grid for specific receiving tube, high temperature radiator and sapphire crystal industry etc.

| Commodity | Standard Specification | ||||

| Diameter | mg / 200mm | Length meter | Pool Dia. mm | ||

| Tungsten Wire ( White Tungsten wire,Black Tungsten Wire) | 5-12µm | 0.075-0.44 | ≥1000 | 30, 40, 80 | |

| 12-18µm | 0.44-0.98 | ≥2000 | 30, 40, 80 | ||

| 18-40µm | 0.98-4.85 | ≥1500 | 80 | ||

| 40-80µm | 4.85-19.39 | ≥700 | 80 | ||

| 80-300µm | 19.39-272.71 | ≥500 | 80 120 | ||

| 300-350µm | 272.71-371.19 | ≥500 | 120 | ||

| 350-500µm | - | ≥100 | 210 | ||

| 500-1800µm | - | ≥200 | 350, 600 | ||

| Tungsten Molybdenum Wire | 0.03-0.8mm | MoW50, MoW30, MoW20 | ≥1000 | 350, 600 | |

| 0.8-11.0mm | 600-1000 | 350, 600 | |||

| Tungsten-Rhenium Wire | 3.0-7.0µm | 1%,3%, 5%, 25% Rhenium | 200+300mesh powder available | ||

| 12-1800µm | |||||

| Packing | In iron drum or plywood case, or as customized specification | ||||

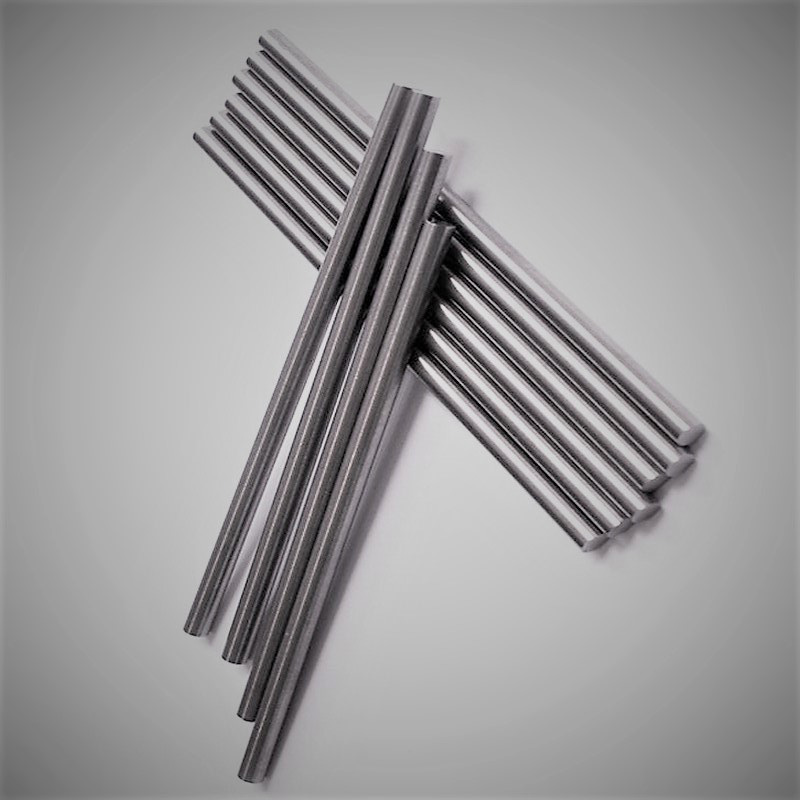

Tungsten Rod/Bar/Plate/Foil/Disc is popular type by rolling, milling, grinding or stamping etc, which are widely used for emission cathodes for electron beam evaporation, high temperature forming rods, support and lad-in wire, printer pin, heating elements of quartz furnace, furnace parts, semiconductor base plate, component for electron tube, tube/boats for sintering of capacitor, X-ray radiation shielding, sputtering targets, vacuum coating vessels and alloy additive etc.

| Commodity | Standard Specification | ||||

| Size | Purity | ||||

| Tungsten Rod | D(2.8-11.0) × 400mm, D(0.8-10.0) × 200mm | 99.5%, 99.7%, 99.95% | |||

| Tungsten Bar | D(2.8-11.0) × 400mm, D(0.8-10.0) × 200mm | ||||

| Tungsten Plate | (30-60) × (10-20) × (100-170), (0.1-100) × 250×L, >1.0×450×L | ||||

| Tungsten Pipe | OD (3-20) × Wall (0.25-5.2) mm | ||||

| Tungsten Sheet | (0.1-0.9) ×450×L, Strip (0.1-0.4) × (0.2-0.8) × L | ||||

| Tungsten Disc | D(10-750) x T (0.5-40) mm | ||||

| Packing | In iron drum or plywood case, or as customized specification | ||||

Procurement Tips

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- ISO9001:2015 Certified

- CPT/CIP/FOB/CFR Terms By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- Quality Inspection By Sate-of-the-art Facility

- Rohs/REACH Regulations Approval

- Non-Disclosure Agreements NDA

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment

Cleaned Tungsten Wire

Black Tungsten Wire

related products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu